Alignment – but which components?

It’s amazing what you can adjust on a telescope. But there are some things that you should not attempt by yourself.

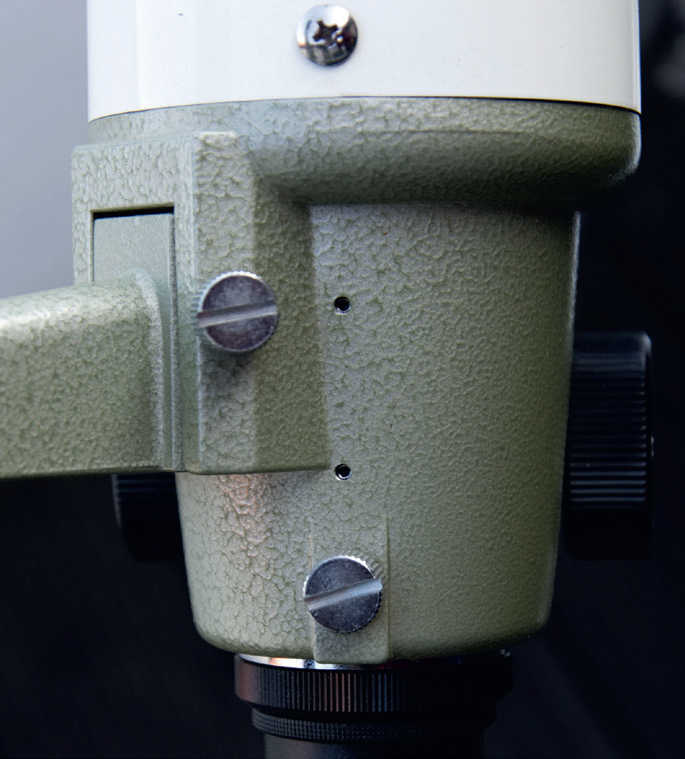

Adjustment screws should always be easily accessible and easy to operate. S. Wienstein

Adjustment screws should always be easily accessible and easy to operate. S. WiensteinAlignment will help you to get the most out of your telescope. In the first section we take a look at what can and should be adjusted.

Do your own telescope alignment? It’s a subject that brings fear to the heart of many star fans. You rely on the fact that the instrument was collimated in the factory – and has not been subjected to any stress since then. And even if it has been, it doesn’t need to be an issue as long as you are certain that the telescope is producing a good image. However, it can be assumed that this attitude means that many telescopes are delivering far short of their true performance capabilities.

Correct alignment should always be seen as the key to obtaining the best performance from your telescope. To do this, it is important to know what can be aligned, how to approach this alignment successfully, and how to improve the range of adjustment options available to you.

What can and should be aligned?

Whatever happens, the primary mirror and lens assembly should be aligned. We start with the optical axis, that is, that part of the image field that delivers optimal image clarity. Alignment of all the individual elements, such as the secondary mirror, correctors, focuser, and zenith mirror or prism, ensures that the optical axis is centred in the focuser and thus also centred in the eyepiece and camera. And it must remain there, even if the focuser or the zenith mirror is rotated.

When to call the experts

Leicht zu übersehen – dieser Okularauszug

kann mit kleinen Madenschrauben auf die

richtige Spur gebracht werden. S. Wienstein

Leicht zu übersehen – dieser Okularauszug

kann mit kleinen Madenschrauben auf die

richtige Spur gebracht werden. S. WiensteinThe lenses inside an objective or corrector are adjusted by means of spacers or spacer rings. The precision optics engineer selects spacers of a precisely graded material thickness. The lenses are additionally rotationally collimated. Thereafter they should not be further rotated, and the spacers must also remain in place, otherwise they will lose their positioning. Such a lens is better left alone. If you really do need to take it apart, for example after water damage or because of fungal infestation, you should look for pencil alignment marks on the matte lens edge – or make some yourself. Waterproof pens risk being easily washed off with solvents such as isopropanol.

Spacer rings are commonly seen in low-cost lenses for alignment purposes. They are made of a flexible material, which is displaced and deformed by small grub screws in the socket. This deformation then shifts and tilts the lens due to the lens curvature. Here too, you should not change anything unless you really know what you are doing, because if you tighten the screws too much, they can stick to the lens edge and cause a fracture or worse.

Where the alignment is fixed

In some cases, different optical surfaces are permanently connected to one another and cannot be adjusted. The most common example is the smaller Maksutov Cassegrain. Whilst in larger Maks the secondary mirror is usually separated from the meniscus lens, smaller instruments feature an optical design in which the secondary mirror is simply vapour-deposited onto the back of the meniscus lens. In rare cases, the secondary mirror is fixed in place. As a result, not only are the three surfaces fixed together, but with regard to the light path, the secondary mirror is separated from the rest of the corrector by several centimetres of light path and the primary mirror. For such instruments, you have to concentrate your alignment effort on this element. If the meniscus lens is accurately manufactured, this can make alignment much easier, because all other elements can then be aligned with the meniscus lens.

Author: Sven Wienstein / Licence: Oculum Verlag GmbH